Automatic high-speed A-type laser pipe cutting machine

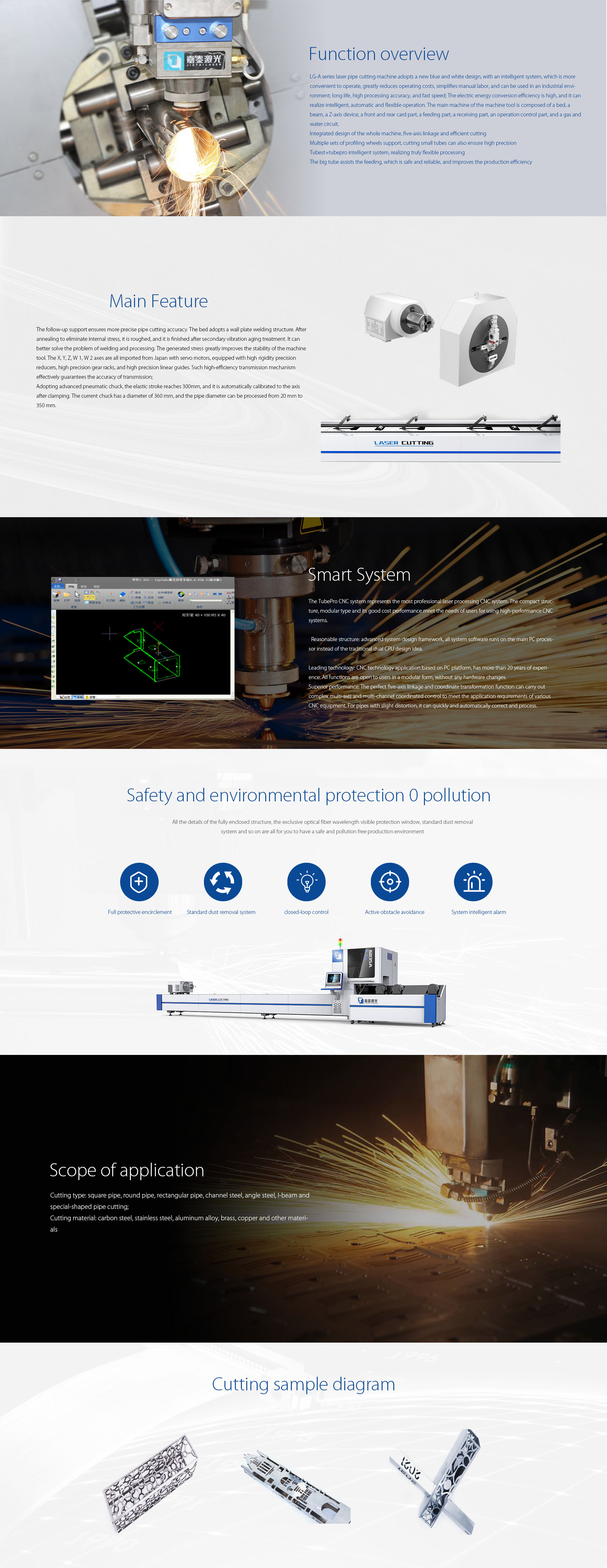

Function overview

LG-A series laser pipe cutting machine adopts a new blue and white design, with an intelligent system, which is more convenient to operate, greatly reduces operating costs, simplifies manual labor, and can be used in an industrial environment; long life, high processing accuracy, and fast speed; The electric energy conversion efficiency is high, and it can realize intelligent, automatic and flexible operation. The main machine of the machine tool is composed of a bed, a beam, a Z-axis device, a front and rear card part, a feeding part, a receiving part, an operation control part, and a gas and water circuit. Integrated design of the whole machine, five-axis linkage and efficient cutting Multiple sets of profiling wheels support, cutting small tubes can also ensure high precision Tubest+tubepro intelligent system, realizing truly flexible processing The big tube assists the feeding, which is safe and reliable, and improves the production efficiency

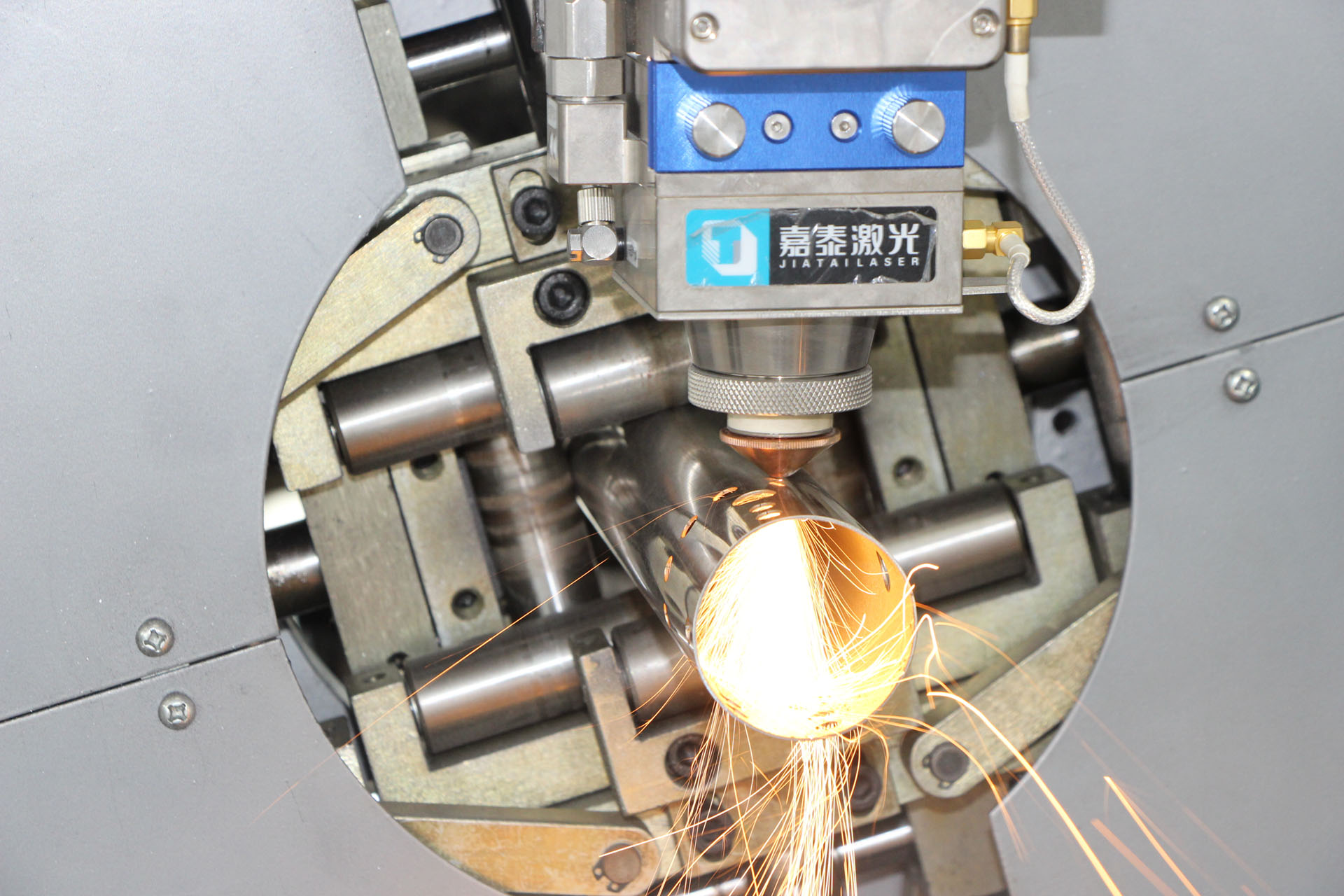

Main Feature

The follow-up support ensures more precise pipe cutting accuracy. The bed adopts a wall plate welding structure. After annealing to eliminate internal stress, it is roughed, and it is finished after secondary vibration aging treatment. It can better solve the problem of welding and processing. The generated stress greatly improves the stability of the machine tool. The X, Y, Z, W 1, W 2 axes are all imported from Japan with servo motors, equipped with high rigidity precision reducers, high precision gear racks, and high precision linear guides. Such high-efficiency transmission mechanism effectively guarantees the accuracy of transmission; Adopting advanced pneumatic chuck, the elastic stroke reaches 300mm, and it is automatically calibrated to the axis after clamping. The current chuck has a diameter of 360 mm, and the pipe diameter can be processed from 20 mm to 350 mm.

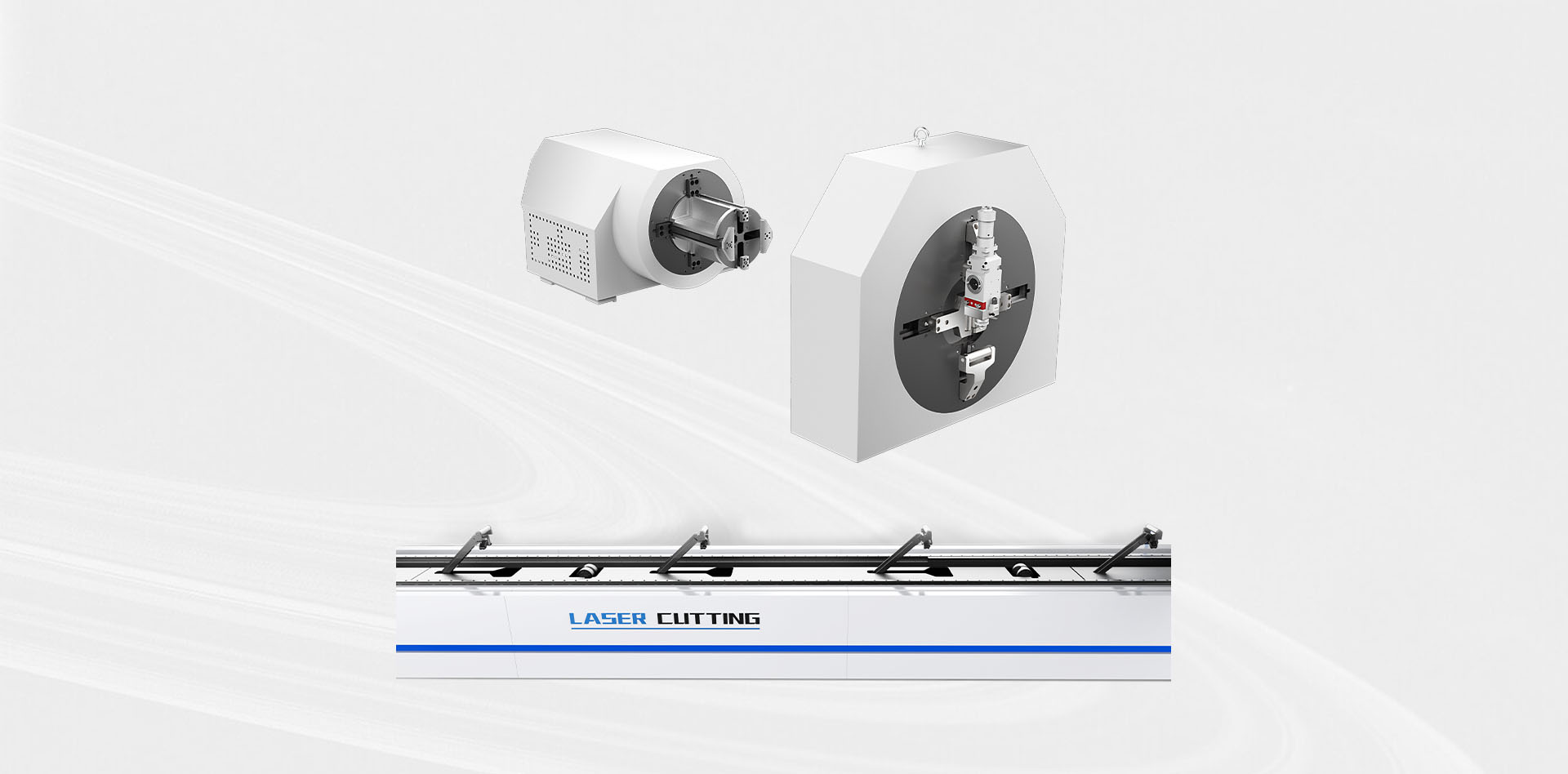

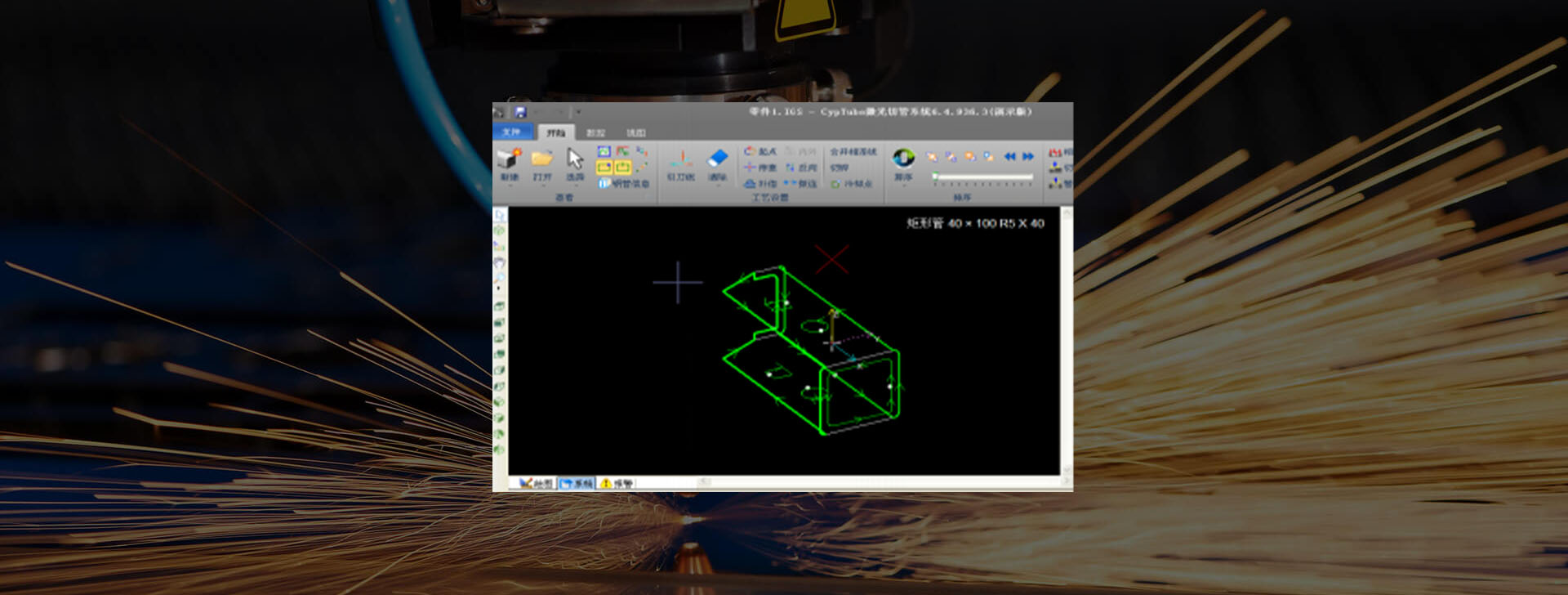

Smart System

The TubePro CNC system represents the most professional laser processing CNC system. The compact structure, modular type and its good cost performance meet the needs of users for using high-performance CNC systems. Reasonable structure: advanced system design framework, all system software runs on the main PC processor instead of the traditional dual CPU design idea. Leading technology: CNC technology application based on PC platform, has more than 20 years of experience. All functions are open to users in a modular form, without any hardware changes. Superior performance: The perfect five-axis linkage and coordinate transformation function can carry out complex multi-axis and multi-channel coordinated control to meet the application requirements of various CNC equipment. For pipes with slight distortion, it can quickly and automatically correct and process.

Safety and environmental protection 0 pollution

All the details of the fully enclosed structure, the exclusive optical fiber wavelength visible protection window, standard dust removal system and so on are all for you to have a safe and pollution free production environment

Scope of application

Cutting type: square pipe, round pipe, rectangular pipe, channel steel, angle steel, I-beam and special-shaped pipe cutting; Cutting material: carbon steel, stainless steel, aluminum alloy, brass, copper and other materials

Cutting sample diagram

Popular products:

Contact Us

86-577-88605158

86-577-88605158

Zhejiang Jiatai Laser Technology Co., Ltd. 浙ICP备15027359号-3 Powered by www.300.cn

Language

Language  中文

中文 English

English Español

Español عربى

عربى