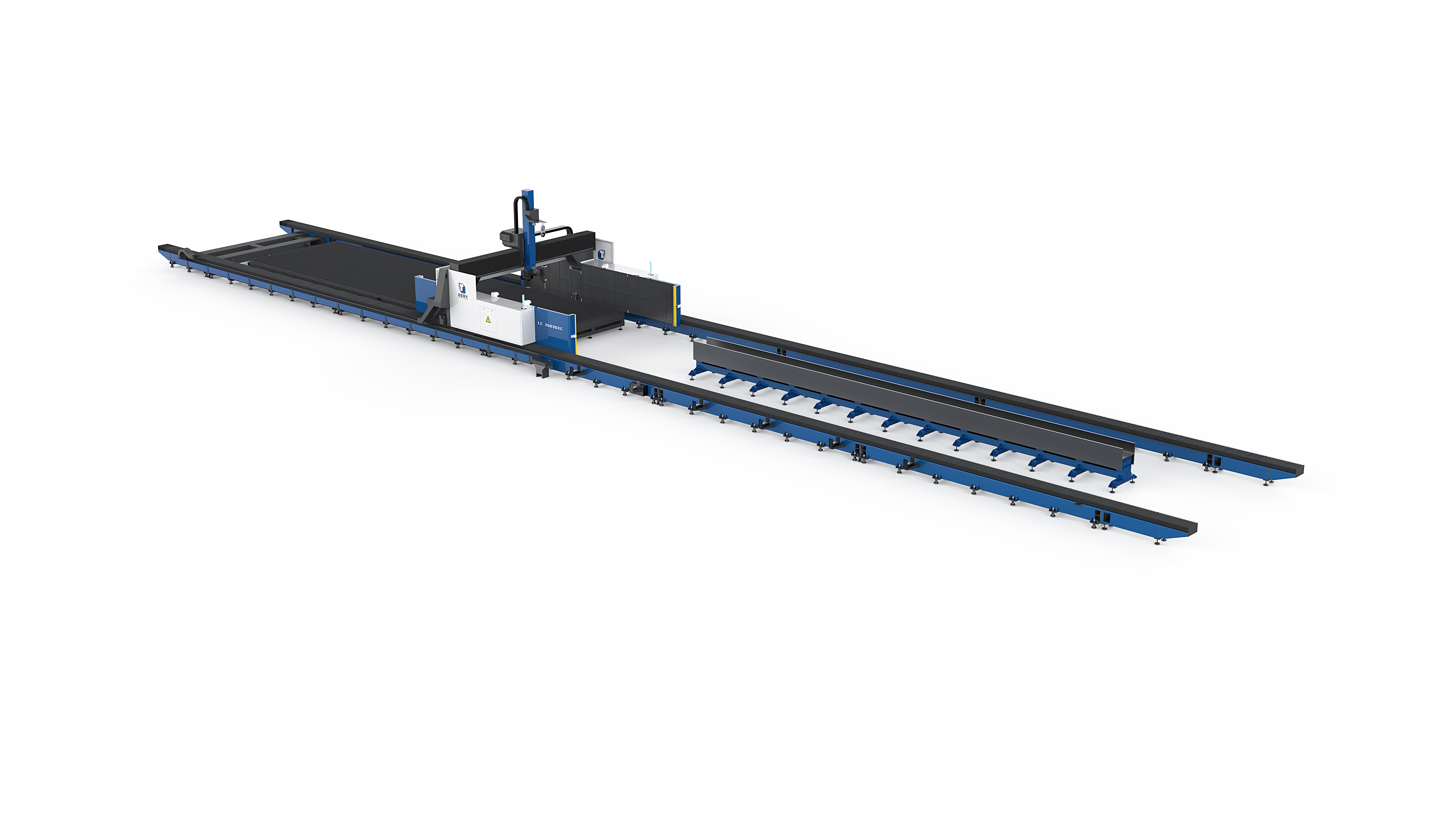

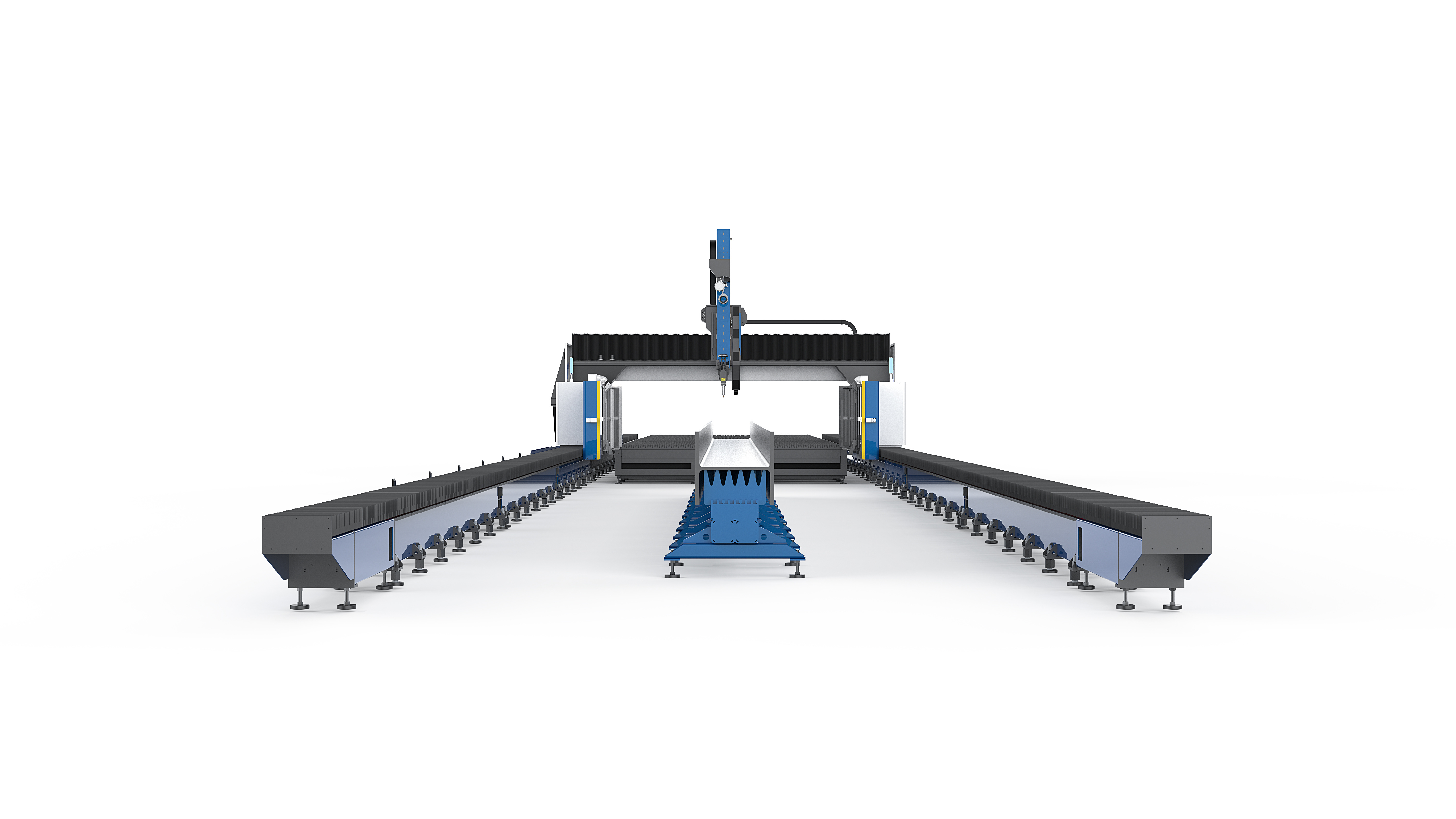

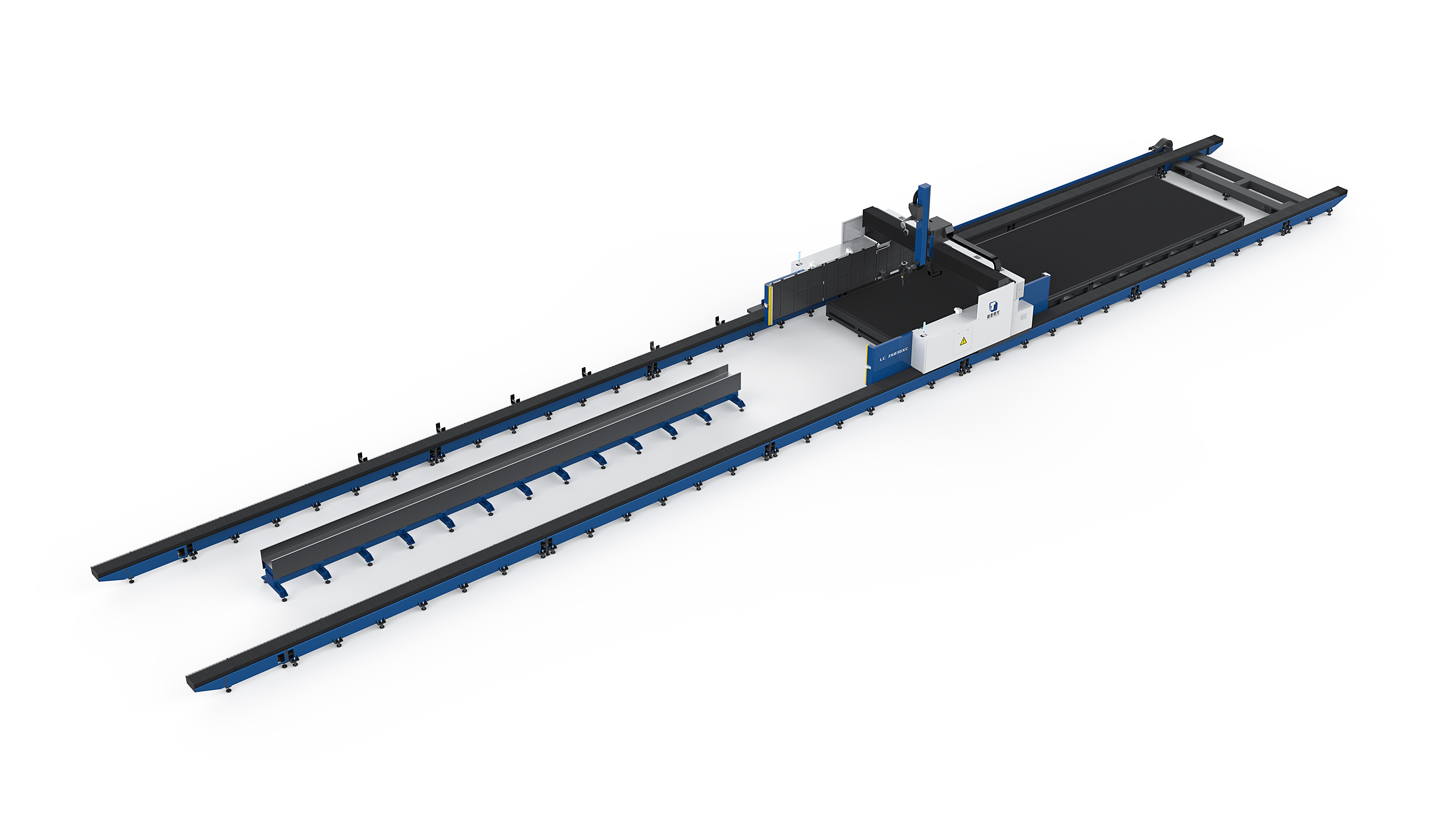

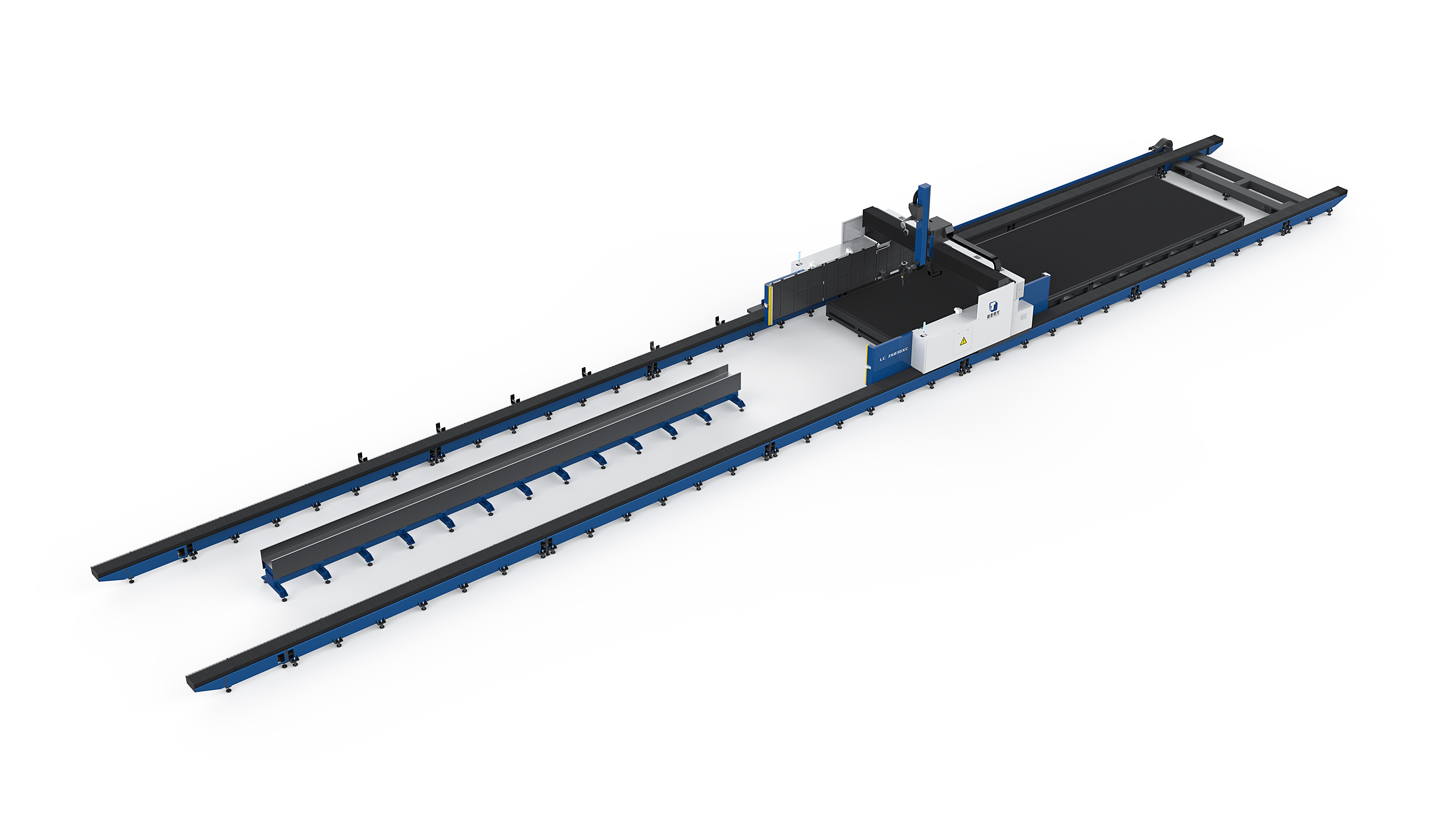

3D Five-axis H-shape Steel Laser Cutting Equipment XC Series

3D Five-axis H-shape Steel Laser Cutting Equipment XC Series

Product Details

Specifications

Video

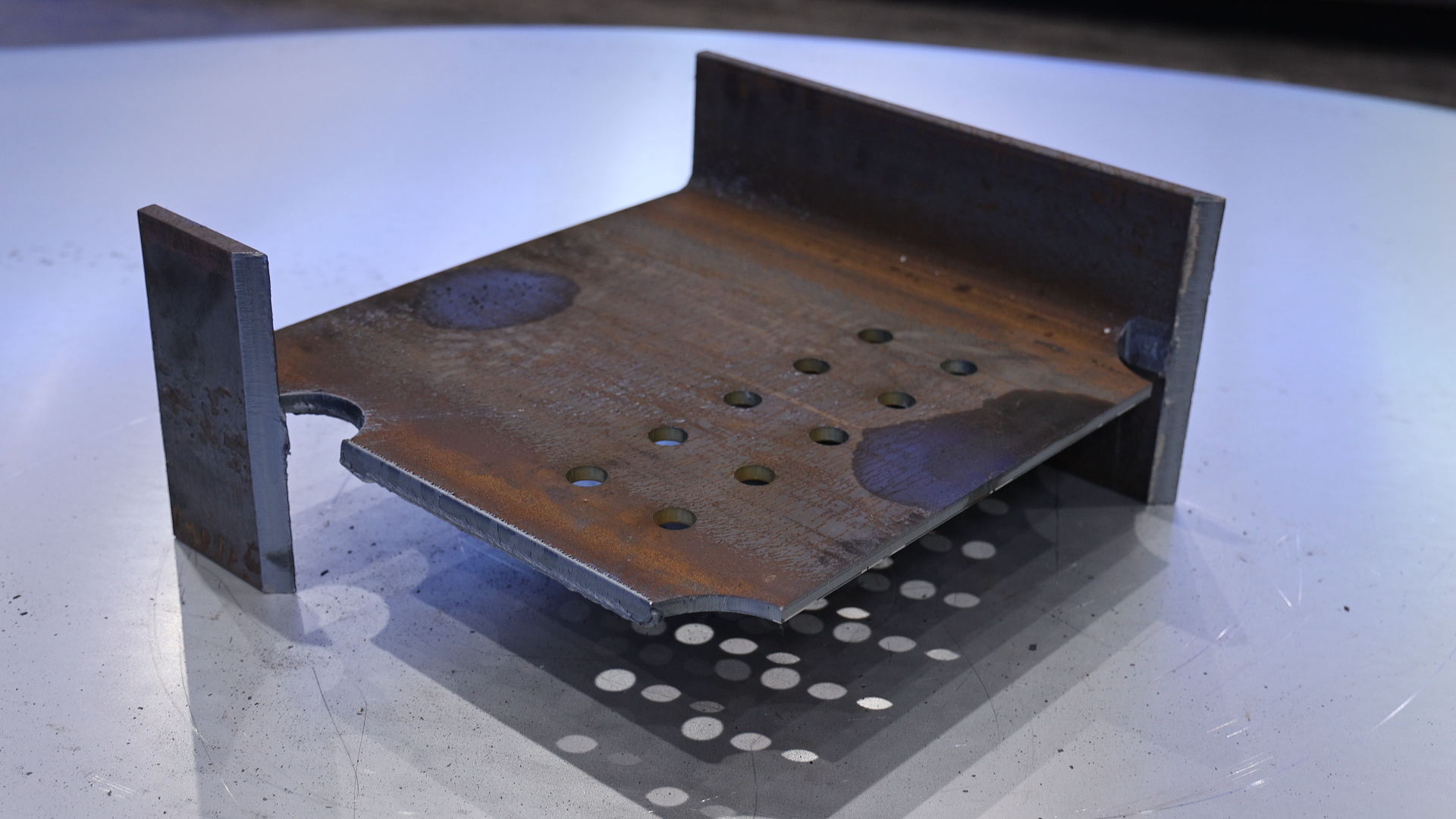

Sample display

Three-dimensional five-axis H-beam laser cutting equipment is a special laser cutting machine designed for section steel processing.

lt supports dual-station processing of section steel, correction compensation for section steel bending, professional nesting of section steel, digital factory management, etc.

lt can perfectly work with Tekla design software, and it has high precision products and fast speed.

① Intelligent RTCP calibration

It is used to correct the five-axis mechanical accuracy in the equipment debugging stage, and can ensure the accurate cutting positioning in the subsequent cutting process after the debugging is completed.

②BCW profile scanning

Because the profile will be deformed, if you cut it directly according to the drawing, the cutting size will be inaccurate, there is the risk of hitting the cutting head, and the problem of unable to cut off the profile, cutting dislocation and so on.

BCW profile scanning function can scan the profile before processing, transfer the data to the processing system in real time, complete the point cloud computing of the scan track in real time, real-time modeling, clear the deformation area of the steel, real-time compensation, to ensure the smooth cutting.

③Tekla seamless docking

The design drawing made by Tekla software can be directly imported into the nesting system and sent to the equipment for use without conversion.

④ Cycle nesting

Compared with traditional nesting material, it can save material

⑤ Over welding hole cutting

The over-welded hole processing function introduced by Bochu steel cutting system can directly cut the over-welded hole, and through process debugging, different root effects can be cut according to demand.

| Model Number | LC26030XC |

| Working Area | Width H≤1200mm(Optional) |

| Height B≤600mm(Optional) | |

| Length L≤12500mm | |

| Laser Power | 12KW、20KW(Optional) |

| XAxis Travel | 26000mm |

| YAxis Travel | 3000mm |

| ZAxis Travel | 1200mm |

| A-axis (Rotary Axis) | ±90° |

| C-axis (Rotary Axis) | ±90° |

| XYIZ Axis Positioning Accuracy | ±0.08mm/m |

* The parameters are for reference only. The actual operating speed is subject to the actual configuration of the motor.

3D Five-axis H-shape Steel Laser Cutting Equipment XC Series

Laser cutting machine is a kind of high precision and high efficiency equipment in the field of modern industrial manufacturing, which is widely used in metal processing, automobile manufacturing, shipbuilding, construction machinery and other industries. Its core technology lies in the combination of laser technology and mechanical technology, which makes the traditional cutting process glow with new vitality.

Key words:

Classification:

关键词: 3D Five-axis H-shape Steel Laser Cutting Equipment XC Series

E-mail:

Details

The principle of 1. laser cutting machine

The laser cutting machine uses a laser to generate a high-power laser beam to irradiate the target material to instantly melt or vaporize it. At the same time, the high-speed airflow blows away the molten material, so as to achieve the purpose of cutting. The whole process has high precision, fast speed and small heat affected area.

Features of 2. laser cutting machine

1. High precision: The cutting accuracy of the laser cutting machine is very high, which can reach the micron level, which ensures the processing quality of the workpiece.

2. High efficiency: The laser cutting speed is fast, which greatly shortens the processing cycle.

3. Flexible: The laser cutting machine can adapt to the cutting needs of various shapes and materials, with extremely high flexibility.

4. Non-contact processing: Laser cutting is a non-contact processing method and will not cause mechanical pressure on the workpiece.

Application of 3. laser cutting machine

1. Automobile manufacturing: laser cutting machine is used for cutting automobile body, engine and other parts.

2. Sheet metal processing: used for cutting and punching of various metal plates.

Construction machinery: used to manufacture the key components of large machinery and equipment.

Medical devices: precision components used in the manufacture of medical devices.

Future development of 4. laser cutting machine

With the progress of science and technology, the performance of laser cutting machine will be further improved, such as higher cutting speed, higher precision, lower cost and so on. At the same time, with the development of industrial 4.0 and intelligent manufacturing, laser cutting machines will achieve deeper integration with other equipment to achieve intelligent and automated production. In addition, the application of laser cutting machines in high-end manufacturing fields such as new energy and aerospace will be further expanded.

In short, laser cutting machine is the pioneer of modern industrial manufacturing, with its high precision, high efficiency, high flexibility, widely used in various fields. With the continuous advancement of technology, laser cutting machines will play a greater role in the future and inject new impetus into the development of the manufacturing industry.

Three-dimensional five-axis H-beam laser cutting equipment is a special laser cutting machine designed for section steel processing.

lt supports dual-station processing of section steel, correction compensation for section steel bending, professional nesting of section steel, digital factory management, etc.

lt can perfectly work with Tekla design software, and it has high precision products and fast speed.

① Intelligent RTCP calibration

It is used to correct the five-axis mechanical accuracy in the equipment debugging stage, and can ensure the accurate cutting positioning in the subsequent cutting process after the debugging is completed.

②BCW profile scanning

Because the profile will be deformed, if you cut it directly according to the drawing, the cutting size will be inaccurate, there is the risk of hitting the cutting head, and the problem of unable to cut off the profile, cutting dislocation and so on.

BCW profile scanning function can scan the profile before processing, transfer the data to the processing system in real time, complete the point cloud computing of the scan track in real time, real-time modeling, clear the deformation area of the steel, real-time compensation, to ensure the smooth cutting.

③Tekla seamless docking

The design drawing made by Tekla software can be directly imported into the nesting system and sent to the equipment for use without conversion.

④ Cycle nesting

Compared with traditional nesting material, it can save material

⑤ Over welding hole cutting

The over-welded hole processing function introduced by Bochu steel cutting system can directly cut the over-welded hole, and through process debugging, different root effects can be cut according to demand.

Related Products

undefined

Online message

Any questions? Get in touch. We'd love to hear from you.