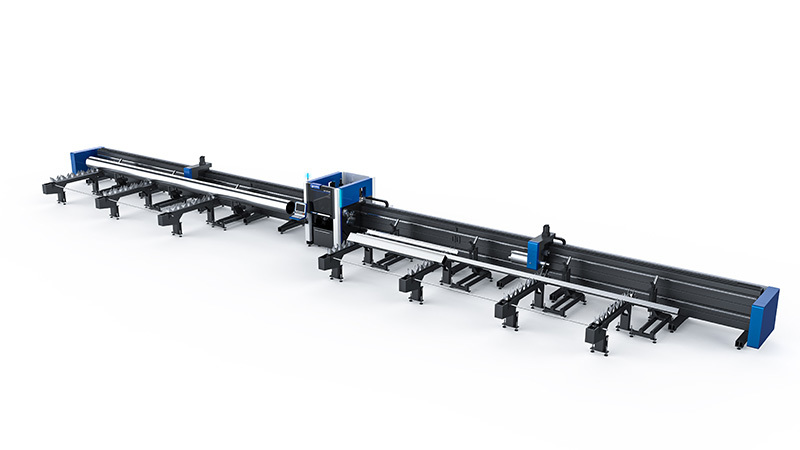

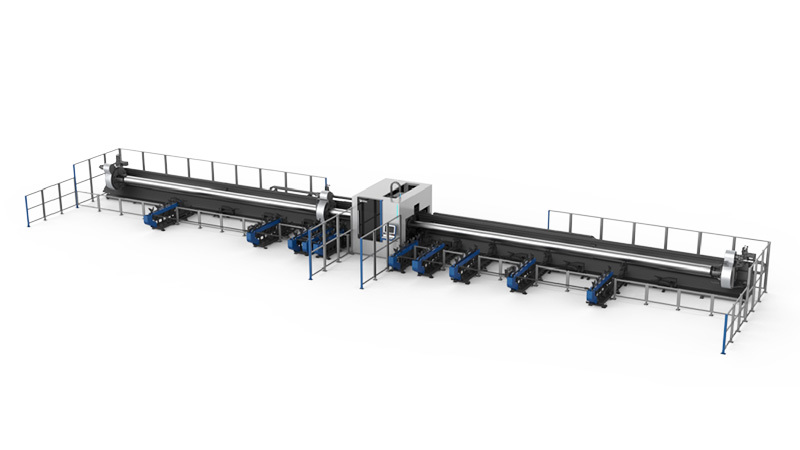

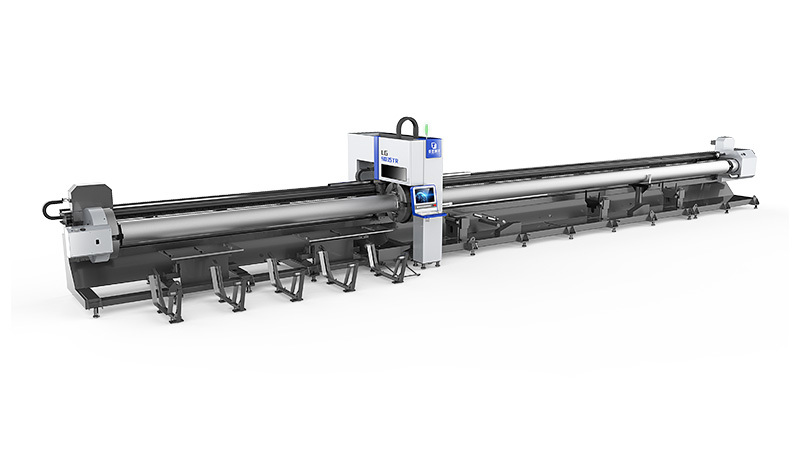

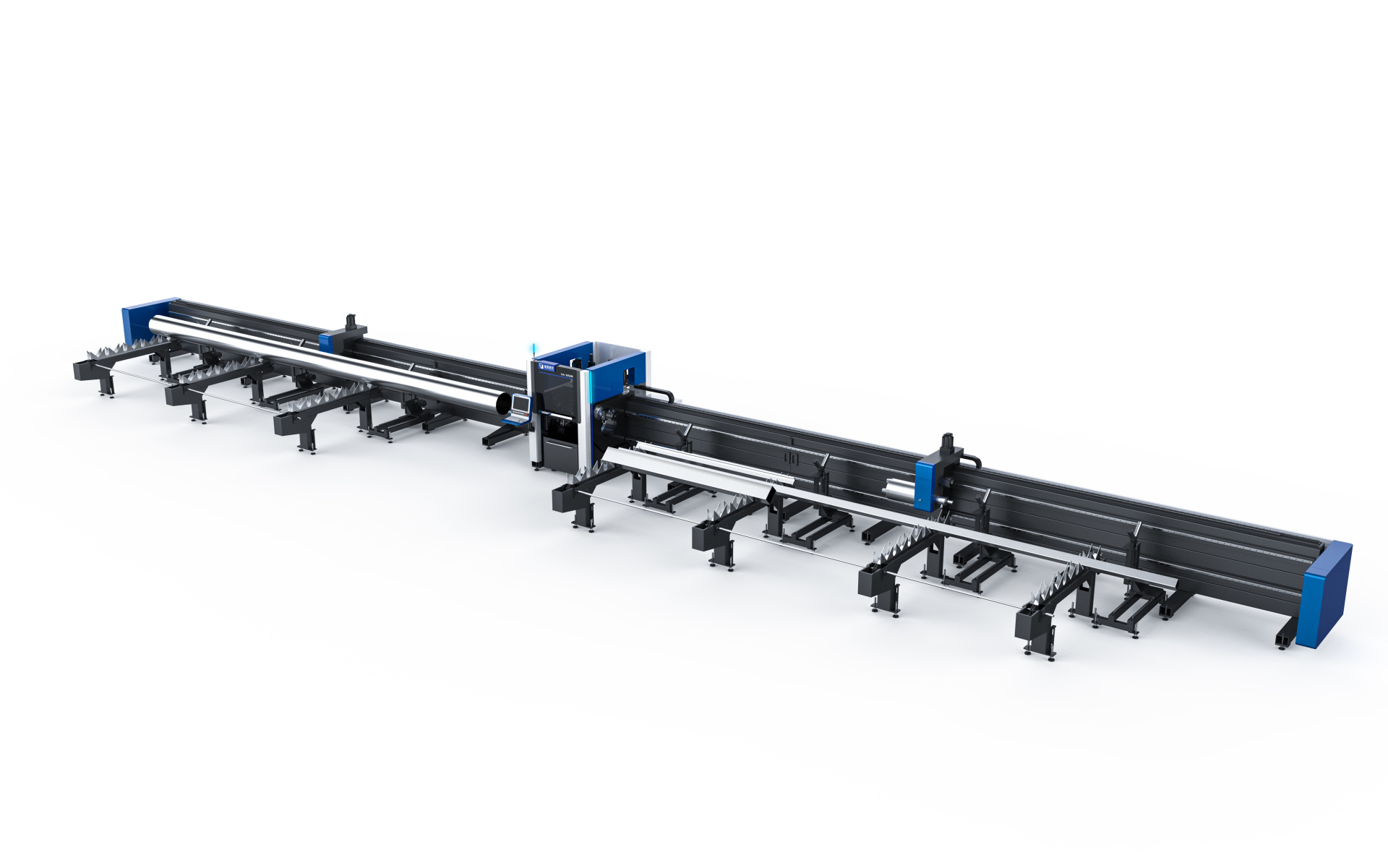

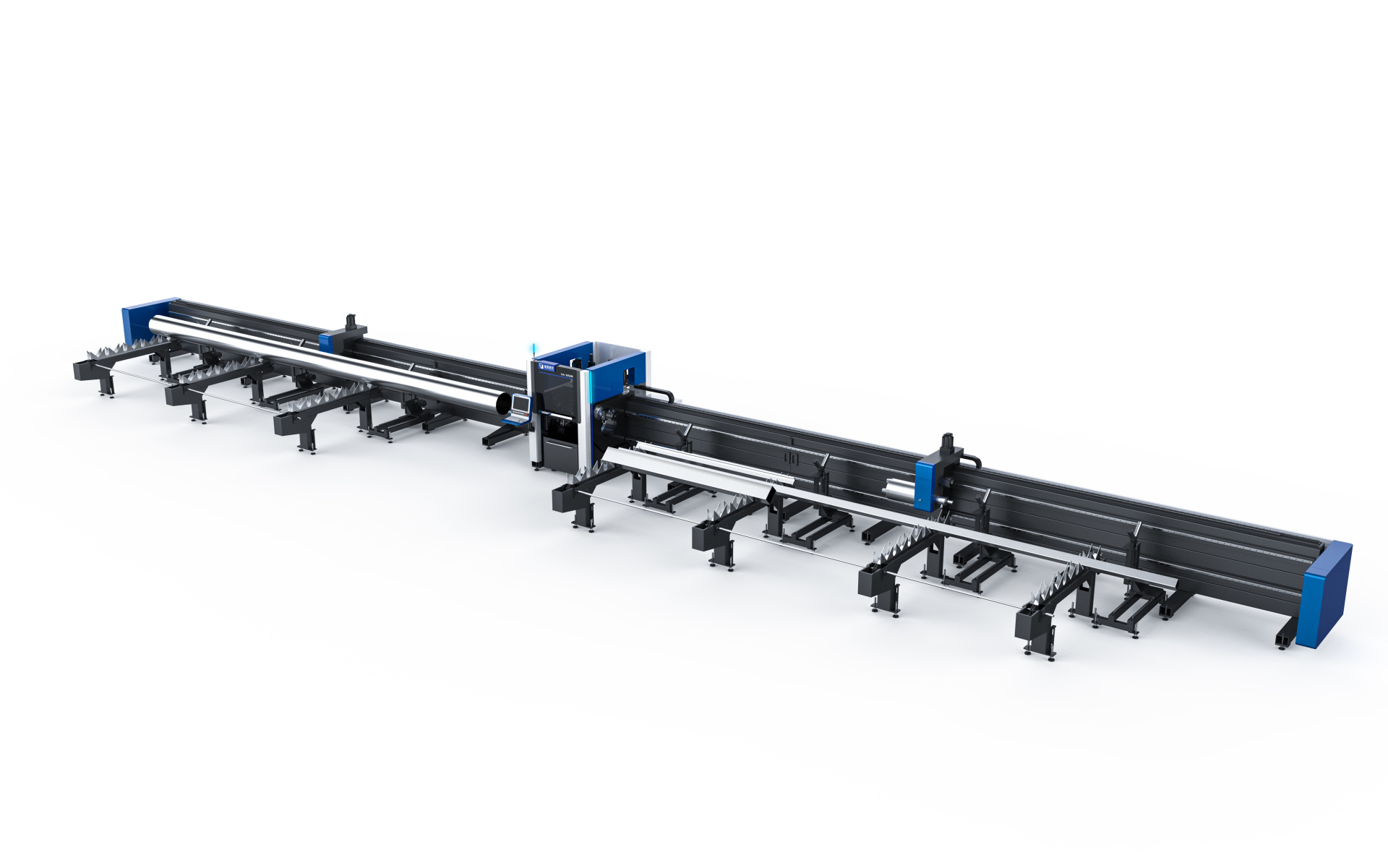

Laser Pipe Cutting Machine Heavy Duty Series (Four Chucks)

Laser Pipe Cutting Machine Heavy Duty Series (Four Chucks)

Product Details

Specifications

Video

Sample display

① Four-chuck design, easy clamping of overweight tubes, man-machine loading and unloading separation

② Modular bed structure, strong functional expandability, easy transportation.

③ Equipped with semi-automatic loading and unloading as standard, supports automatic pipe centering and material head detection.

④ It can realize zero tailings processing, center-seeking and correction, multi-pipe type cutting and other functional applications.

⑤ A bevel cutting function can be equipped.

| Model Number | JTLG12052AS | JTLG12052FS |

| Tube Dimension | Round Tube:80-508mm*12200mm Square Tube:80*80-350*350mm*12200mm |

Round Tube:Φ80-508mm*12200mm Square Tube:80*80-500*500mm*12200mm |

| Laser Power | 6KW-20KW (Optional) | |

| XY Axis Maximum Positioning Speed | 50m/min | |

| XY AxisMax Acceleration | 0.5G | |

| W-Axis Maximum Speed | 50rpm | |

| Loading Weight | 2000KG | |

* The parameters are for reference only. The actual operating speed is subject to the actual configuration of the motor.

Laser Pipe Cutting Machine Heavy Duty Series (Four Chucks)

Laser cutting machine is a kind of high precision and high efficiency equipment in the field of modern industrial manufacturing, which is widely used in metal processing, automobile manufacturing, shipbuilding, construction machinery and other industries. Its core technology lies in the combination of laser technology and mechanical technology, which makes the traditional cutting process glow with new vitality.

Key words:

Classification:

关键词: Laser Pipe Cutting Machine Heavy Duty Series (Four Chucks)

E-mail:

Details

The principle of 1. laser cutting machine

The laser cutting machine uses a laser to generate a high-power laser beam to irradiate the target material to instantly melt or vaporize it. At the same time, the high-speed airflow blows away the molten material, so as to achieve the purpose of cutting. The whole process has high precision, fast speed and small heat affected area.

Features of 2. laser cutting machine

1. High precision: The cutting accuracy of the laser cutting machine is very high, which can reach the micron level, which ensures the processing quality of the workpiece.

2. High efficiency: The laser cutting speed is fast, which greatly shortens the processing cycle.

3. Flexible: The laser cutting machine can adapt to the cutting needs of various shapes and materials, with extremely high flexibility.

4. Non-contact processing: Laser cutting is a non-contact processing method and will not cause mechanical pressure on the workpiece.

Application of 3. laser cutting machine

1. Automobile manufacturing: laser cutting machine is used for cutting automobile body, engine and other parts.

2. Sheet metal processing: used for cutting and punching of various metal plates.

Construction machinery: used to manufacture the key components of large machinery and equipment.

Medical devices: precision components used in the manufacture of medical devices.

Future development of 4. laser cutting machine

With the progress of science and technology, the performance of laser cutting machine will be further improved, such as higher cutting speed, higher precision, lower cost and so on. At the same time, with the development of industrial 4.0 and intelligent manufacturing, laser cutting machines will achieve deeper integration with other equipment to achieve intelligent and automated production. In addition, the application of laser cutting machines in high-end manufacturing fields such as new energy and aerospace will be further expanded.

In short, laser cutting machine is the pioneer of modern industrial manufacturing, with its high precision, high efficiency, high flexibility, widely used in various fields. With the continuous advancement of technology, laser cutting machines will play a greater role in the future and inject new impetus into the development of the manufacturing industry.

① Four-chuck design, easy clamping of overweight tubes, man-machine loading and unloading separation

② Modular bed structure, strong functional expandability, easy transportation.

③ Equipped with semi-automatic loading and unloading as standard, supports automatic pipe centering and material head detection.

④ It can realize zero tailings processing, center-seeking and correction, multi-pipe type cutting and other functional applications.

⑤ A bevel cutting function can be equipped.

Related Products

Online message

Any questions? Get in touch. We'd love to hear from you.